Para evitar atrasos na resposta ao seu pedido, indique o seu WhatsApp/Skype juntamente com a mensagem, para que possamos contactá-lo logo na primeira vez.

Responder-lhe-emos no prazo de 24 horas. Se for um caso urgente, adicione o WhatsApp: +8617862411260 ou WeChat: +8617862411260. Ou cal +8617862411260 diretamente.

Dust problems rarely start big—but they grow fast. Fine particles spread, machines clog, workers breathe in hazards, and soon safety, productivity, and compliance are at risk. A professional dust control mainframe offers a proven solution to stop dust at the source and restore clean, safe air.

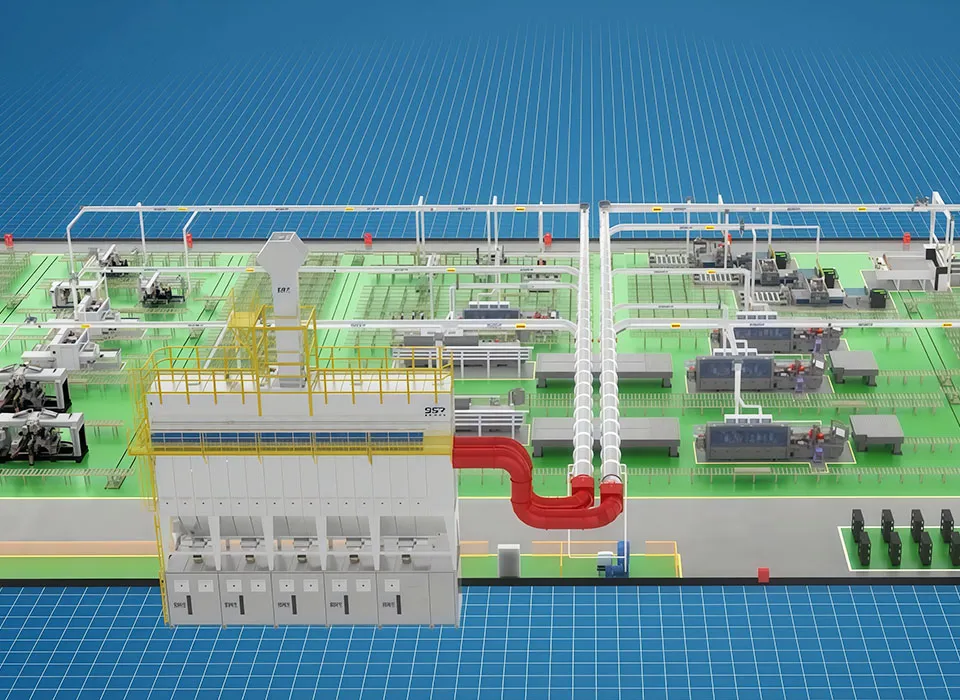

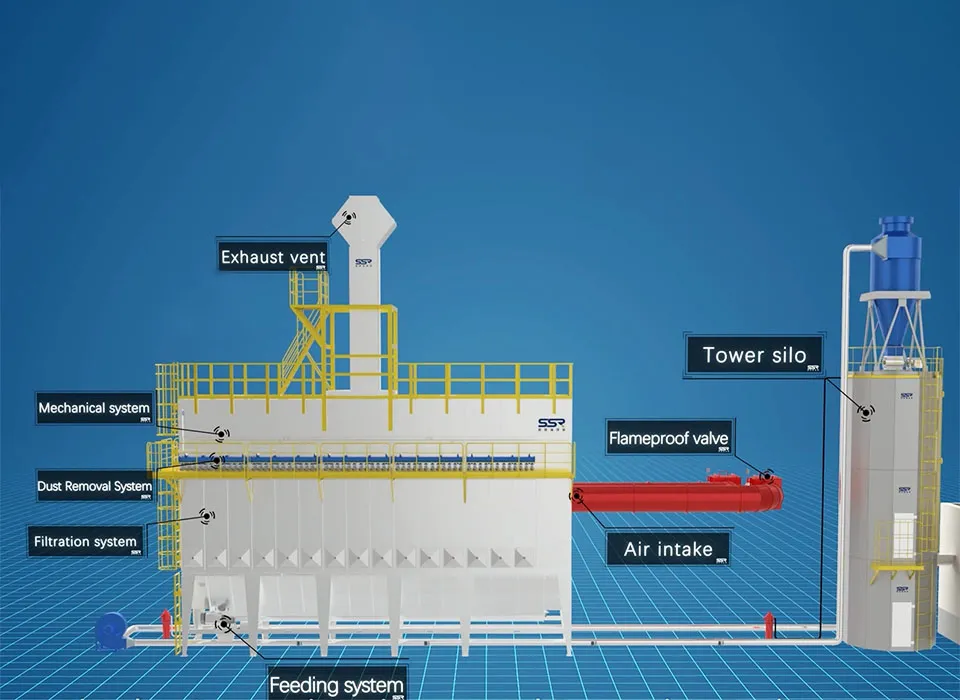

A dust control mainframe is the core of an industrial dust suppression system that captures fugitive dust and airborne particles from multiple workstations. It connects cutting, grinding, conveying, and mixing points into one dust control system—helping companies improve air quality, meet regulatory compliance, and protect both people and equipment.

A dust control mainframe is the central engine of modern dust control. Instead of treating dust at one machine, it manages airborne particles across the whole facility. From woodworking shops to metal fabrication plants, we see dust everywhere—on tools, on floors, and in the air workers breathe.

At Senserui, we design these systems for factories that face daily dust control challenges. Our customers work in environments where respirable dust is more than a nuisance—it’s a serious hazard. By centralizing dust collection, the mainframe helps control dust before it spreads, making operations cleaner and safer from day one.

Dust suppression plays a critical role in keeping workers healthy. Fine dust particles can stay airborne for hours. Over time, they affect lungs, reduce visibility, and increase accident risk.

A well-designed dust suppression system uses airflow, containment, and sometimes atomized mist to bind particles and remove them from the air. This doesn’t just improve working conditions—it builds a safer culture where employees feel protected and valued. In high-risk industries like mining and power generation, dust suppression even helps prevent explosion and combustion hazards.

Most factories struggle with the same issues:

These are not small problems. Fugitive dust spreads quickly through open doors, transfer points, and ventilation systems. Without proper dust management, even a small source becomes a site-wide problem.

That’s why modern dust control solutions focus on stopping dust at the point of generation—before it becomes airborne dust that threatens the entire workplace.

Many people think dust collection and dust suppression do the same job. They don’t—but together they form a complete solution.

Dust collection systems pull contaminated air into filters and baghouses. Dust suppression, on the other hand, uses controlled moisture or mist to suppress dust before it lifts into the air.

When we design systems at Senserui, we combine both approaches. This integrated strategy keeps dust particles under control while reducing water usage and maintaining operational efficiency.

Case study: A mid-size metal fabrication plant faced rising health complaints and failed an environmental inspection. They installed a dust control mainframe connected to welding, grinding, and cutting stations.

Results after six months:

They told us, “We finally feel in control of our air.” That’s the power of a properly installed a dust control system.

No two factories are alike. That’s why dust control must start with proper engineering.

At Senserui, our approach includes:

This process ensures the dust control products you choose fit your space, production rate, and safety needs. A well-planned installation reduces downtime and delivers faster results.

Clean air is no longer optional—it’s expected. Authorities now enforce stricter regulatory compliance for airborne contaminants.

A reliable dust control mainframe helps companies meet both regulatory e environmental compliance standards while boosting employee confidence. When workers breathe cleaner air, productivity rises and absenteeism drops.

From woodworking shops to electronics factories, the same truth applies: good air quality is good business.

At Senserui, we work closely with:

We don’t just sell equipment—we deliver engineered dust control solutions that help our customers protect people, meet standards, and run more efficiently.