Evite que su consulta sea de respuesta tardía, por favor introduzca su WhatsApp/Skype junto con el mensaje, para que podamos ponernos en contacto con usted a la primera.

Le responderemos en un plazo de 24 horas. Si para el caso urgente, por favor agregue WhatsApp: +8617862411260 o WeChat: +8617862411260. O cal +8617862411260 directamente.

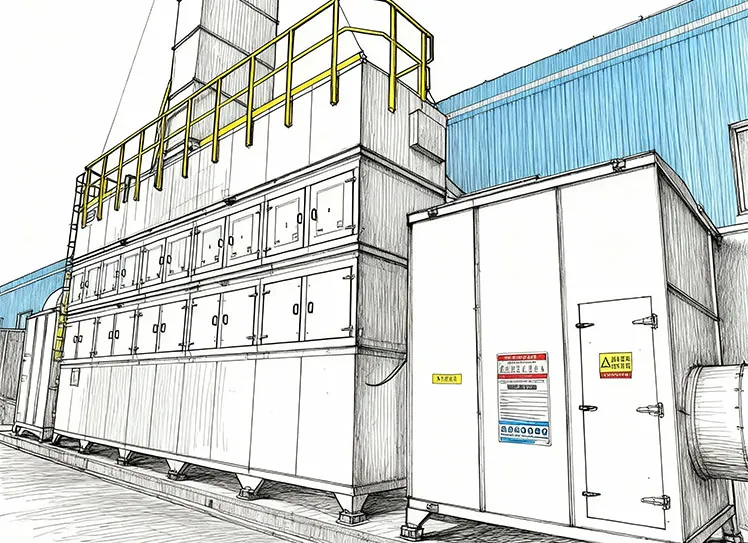

HAC-M is the standard VOCs mainframe for spray booths, leveling rooms, drying/curing, and routine solvent cleaning stations. Using high-iodine honeycomb activated carbon and a modular multi-fan design, it balances footprint, capacity, and maintenance cost. Front/side drawer-type carbon cassette quick-swap, ΔP and breakthrough monitoring, plus optional IoT remote O&M, turn “capture → monitor → replace → record” into a repeatable standard process—ideal for both new builds and retrofits.

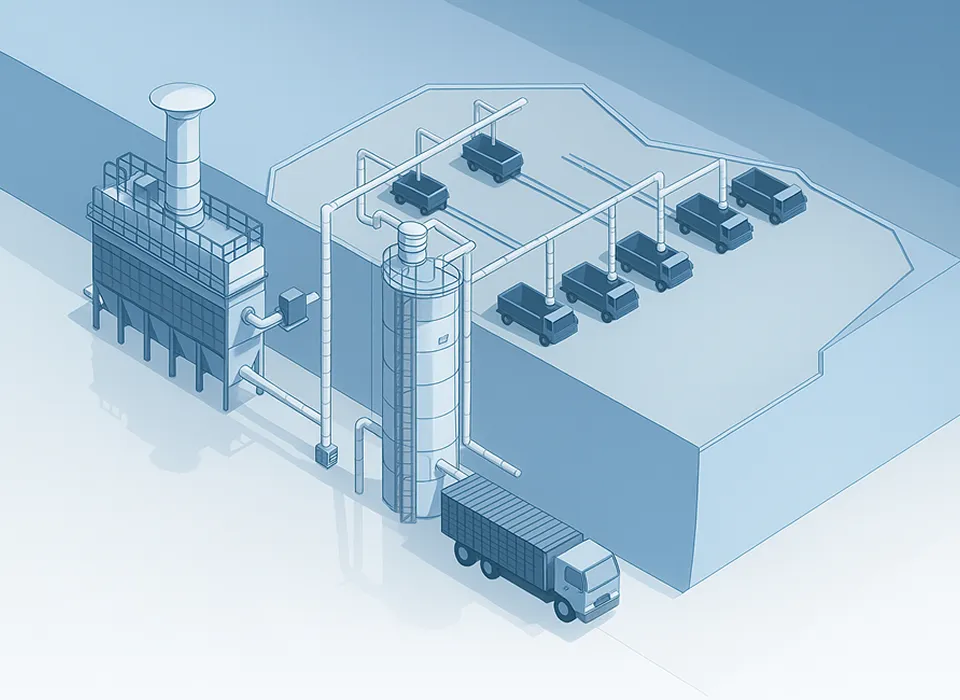

Exhaust gases from processing equipment first pass through a pre-treatment stage, where large dust particles are removed via physical settling. The pre-filtered air then enters the core processing unit, where multiple purification modules are activated. These include activated carbon adsorption, catalytic oxidation, or other customized modules depending on the VOC type and concentration.

As the air flows through the system, harmful substances are removed, and purified air is discharged through the outlet. The system continuously monitors airflow, pressure drop, and equipment status, issuing alerts when maintenance or filter replacement is required. After servicing, the system automatically resets operational data to ensure long-term compliance, efficiency, and full traceability.

Nos comprometemos a entregar a tiempo y a formular planes claros de producción y envío para cada lote de pedidos, a fin de garantizar que los nodos de los proyectos internos del cliente no sufran retrasos.