Sorgunuzun gecikmeli yanıtlanmasından kaçının, lütfen mesajla birlikte WhatsApp / Skype'ınızı girin, böylece sizinle ilk seferde iletişime geçebiliriz.

Size 24 saat içinde cevap vereceğiz. Acil durum için lütfen WhatsApp ekleyin: +8617862411260 veya WeChat: +8617862411260. Veya cal +8617862411260 doğrudan.

Industrial facilities generate invisible risks every minute. Solvent fumes, paint vapors, and airborne gas pollutants quickly turn into safety hazards. Without the right exhaust gas solution, emissions spread, workers suffer, and factories fall out of compliance fast. The HAC Exhaust Gas Treatment Mainframe solves this challenge by capturing and cleaning harmful exhaust gas before it reaches the atmosphere.

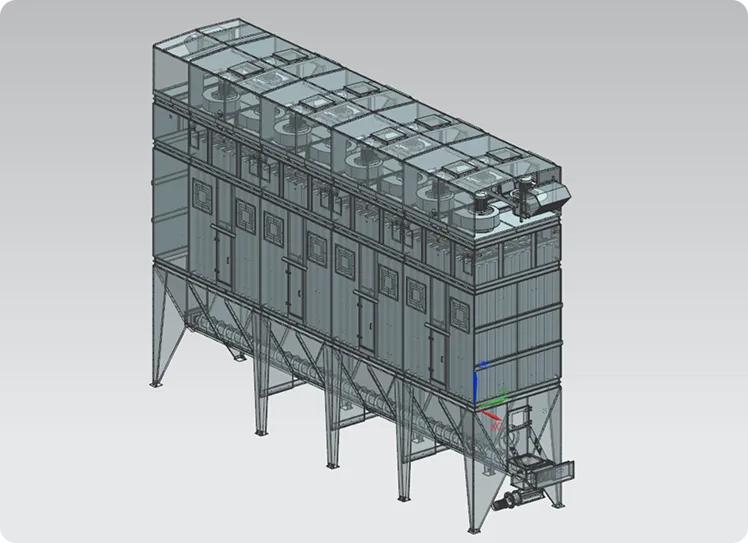

An exhaust gas treatment mainframe is a modular exhaust gas aftertreatment system engineered to filter, neutralize, and clean industrial gas streams—including VOCs, hydrocarbons, and particulate matter—before discharge. It protects workers, reduces emissions, and helps organizations meet compliance with confidence.

A modern exhaust gas treatment mainframe is an engineered aftertreatment system designed to capture and clean VOC-laden dirty exhaust before release. Using staged filtration, adsorption media and engineered airflow, the system acts like a catalyst-free industrial scrubber—removing pollutant molecules and particulate material from the gas stream.

At Senserui, we provide these systems to factories handling dust, fumes and vapor-phase compounds daily—from woodworking and metal fabrication to lithium energy facilities. This is where exhaust gas aftertreatment stops being optional and becomes business-critical.

Industrial exhaust emissions contain many of the same compound classes that diesel exhaust does—including:

In many industries, emissions rise not from an internal combustion engine, but from chemical interactions, spray finishing and thermal drying.

Without an effective exhaust gas aftertreatment system, these vapors become a safety, regulatory and environmental liability.

The HAC series is built on a modular platform—meaning airflow, treatment media and control layers scale with your production volume. While many factories rely on static exhaust systems that clog, overload or degrade, modular units offer:

| Feature | Conventional System | HAC Modular |

|---|---|---|

| Scalability | Fixed capacity | Expandable units |

| Airflow reliability | Single fan | Multi-fan redundancy |

| Maintenance | Manual & reactive | Sensor-driven & planned |

| VOC loading range | Narrow | Broad & adaptable |

| Retrofit capability | Limited | Easy integration |

Senserui designed HAC for EPC contractors, integrators and plant owners who need equipment that evolves with production—not against it.

The HAC system delivers performance through multiple stages analogous to mobile aftertreatment systems:

1. Pre-filter stage

Removes particulate overspray, preventing adsorption media overload—acting like an industrial particulate filter.

2. Activated carbon grid

Here, the “catalyst-equivalent” action happens. Hydrocarbon molecules attach to high-iodine activated carbon micro-pores, replacing the role of SCR catalyst and DPF found in diesel engine systems.

3. Modular fan bank

Multi-fan design ensures that even when load increases, gas flow remains steady—like redundancy in a marine diesel exhaust system.

4. Monitoring and breakthrough sensors

This is the industrial version of online gas purification monitoring—detecting when adsorption approaches saturation and triggering replacement.

The HAC (Modular Standard) serves factories where solvent-based emissions are routine:

Wherever paint cures, resin dries or adhesive evaporates, exhaust emissions increase—and HAC steps in as the industrial exhaust gas cleaning system of record.

A furniture manufacturer operated three spray booths exhausting significant hydrocarbon gas into the workspace and atmosphere. After installing a HAC exhaust gas treatment mainframe:

This transformation reflects a pattern we see globally: clean exhaust = stronger business.

Senserui partners not only with factories, but with the teams designing and installing the next generation of industrial processes:

Every HAC system ships with engineering support, drawings, tuning recommendations and lifecycle servicing guidance—because long-term reliability matters more than first-day performance.