Evite que su consulta sea de respuesta tardía, por favor introduzca su WhatsApp/Skype junto con el mensaje, para que podamos ponernos en contacto con usted a la primera.

Le responderemos en un plazo de 24 horas. Si para el caso urgente, por favor agregue WhatsApp: +8617862411260 o WeChat: +8617862411260. O cal +8617862411260 directamente.

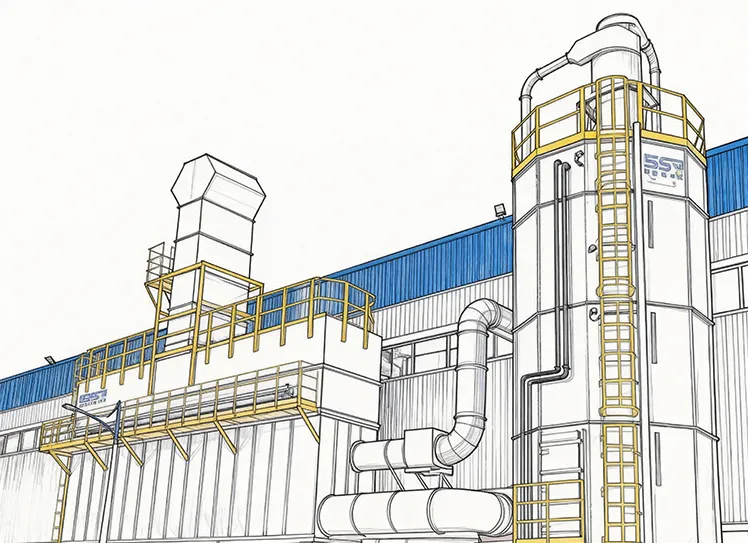

The CC Series is an intelligent modular centralized dust removal system designed specifically for medium and large particle-size dust applications commonly found in heavy manufacturing environments.

Using a multi-fan architecture, built-in fan chambers, and an optimized aerodynamic structure, the CC Series delivers large air volume performance with excellent energy efficiency and operational stability.

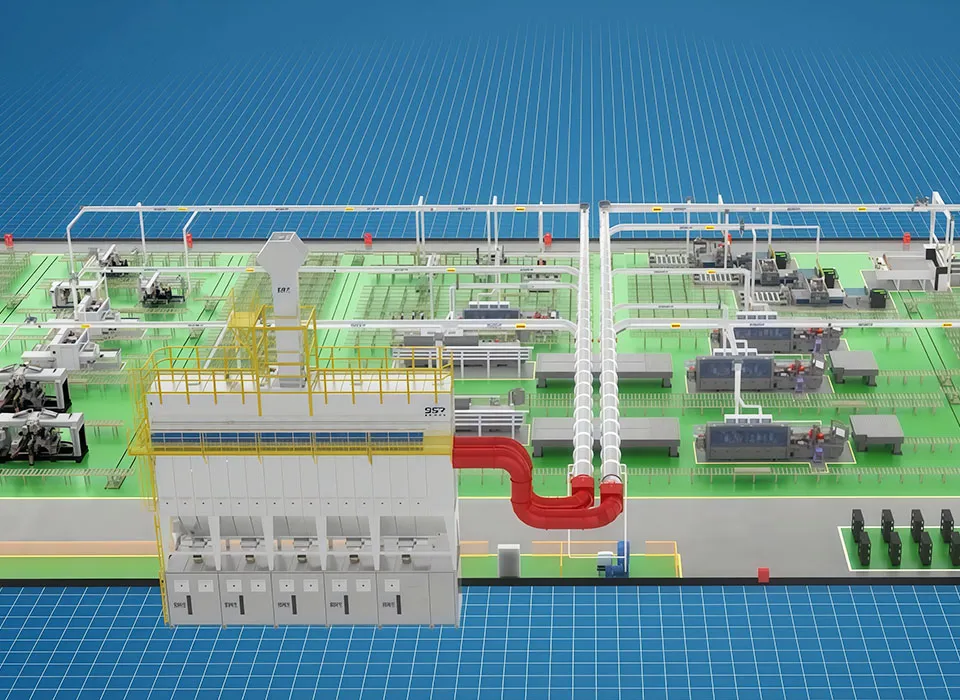

The complete product family covers airflow capacities from 30,000–150,000 m³/h, making it suitable for large-scale, multi-line, and continuous-process dust extraction demands.

Its compact built-in fan layout, <80 dB noise control, comprehensive safety sensors, and automated ash-cleaning system make it ideal for factory upgrades, industrial retrofits, and new plant construction requiring strict dust control compliance.

| Modelo | Potencia (kW) | Volumen de aire (m³/h) | Longitud (mm) | Altura (mm) | Grado Alto (mm) |

| CC30 | 30 | 30,000 | 3500 | 2400 | 8500 |

| CC60 | 60 | 60,000 | 6000 | 2400 | 8500 |

| CC90 | 90 | 90,000 | 9000 | 2400 | 8500 |

| CC120 | 120 | 120,000 | 11,500 | 2400 | 8500 |

| CC150 | 150 | 150,000 | 13,000 | 2400 | 8500 |

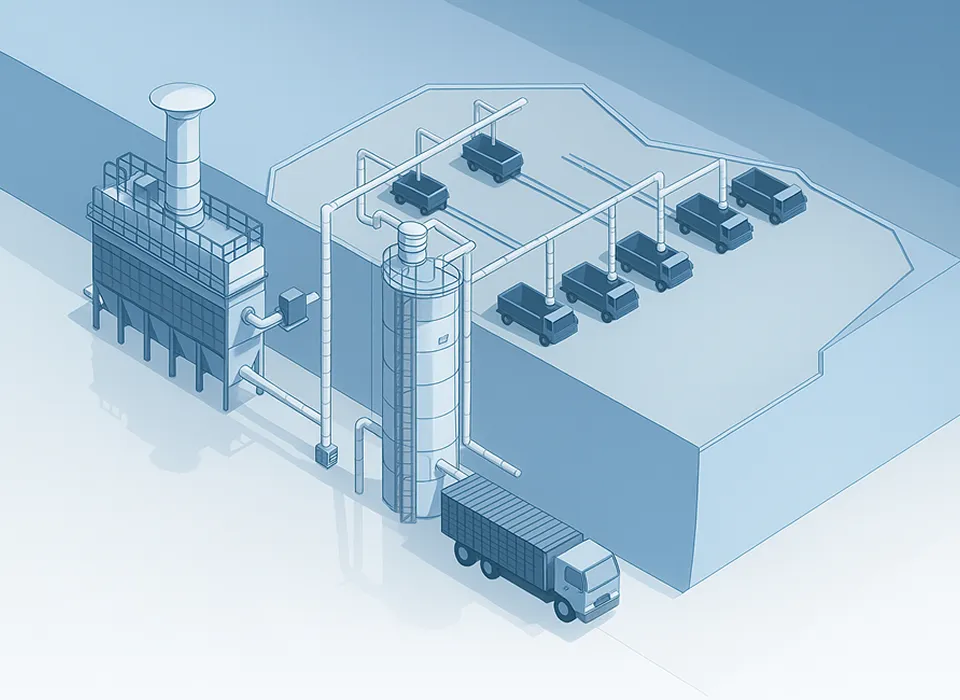

Dust-laden air enters the main chamber, where medium and large particles settle through gravity and directional airflow guidance. Remaining dust is captured uniformly across the filter system.

Real-time monitoring of differential pressure, temperature, and safety triggers maintains optimal filtration performance while ensuring system safety.

Built-in fans operate in a staged manner based on process load, reducing energy waste.

The intelligent ash-cleaning system activates automatically to maintain filtration efficiency without interrupting production.

Paso 4: Limpieza por pulsos

A medida que se acumula el polvo, aumenta la resistencia. El sistema activa la limpieza por chorro pulsante, liberando aire comprimido para desalojar las tortas de polvo de los filtros a la tolva inferior, manteniendo la filtración eficiente e ininterrumpida.

Paso 5: Descarga y recogida

El aire limpio se descarga en el interior (para ahorrar energía) o en el exterior. El polvo recogido cae en la tolva y se extrae regularmente mediante válvulas de descarga para su reciclaje o eliminación unificados.

Nos comprometemos a entregar a tiempo y a formular planes claros de producción y envío para cada lote de pedidos, a fin de garantizar que los nodos de los proyectos internos del cliente no sufran retrasos.