تجنب تأخير الرد على استفسارك، يُرجى إدخال واتساب/سكايب الخاص بك مع الرسالة، حتى نتمكن من الاتصال بك في المرة الأولى.

سنقوم بالرد عليك خلال 24 ساعة. إذا كانت الحالة عاجلة، يرجى إضافة واتساب: +8617862411260 أو WeChat +8617862411260. أو كال +8617862411260 مباشرةً.

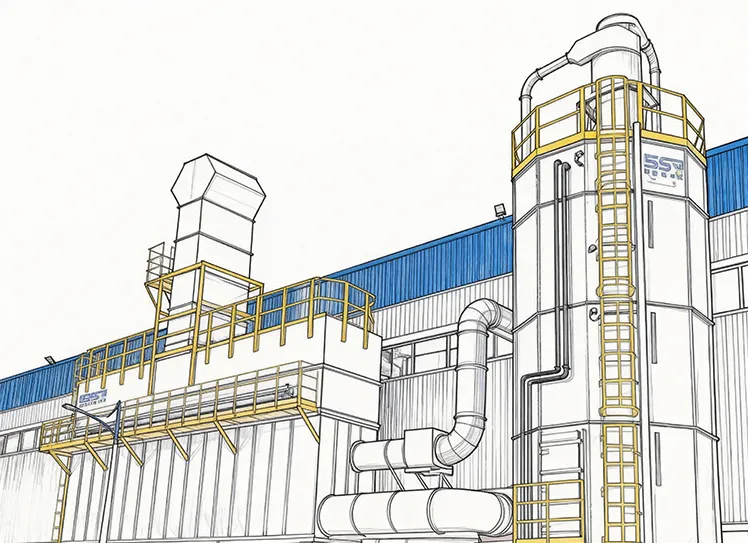

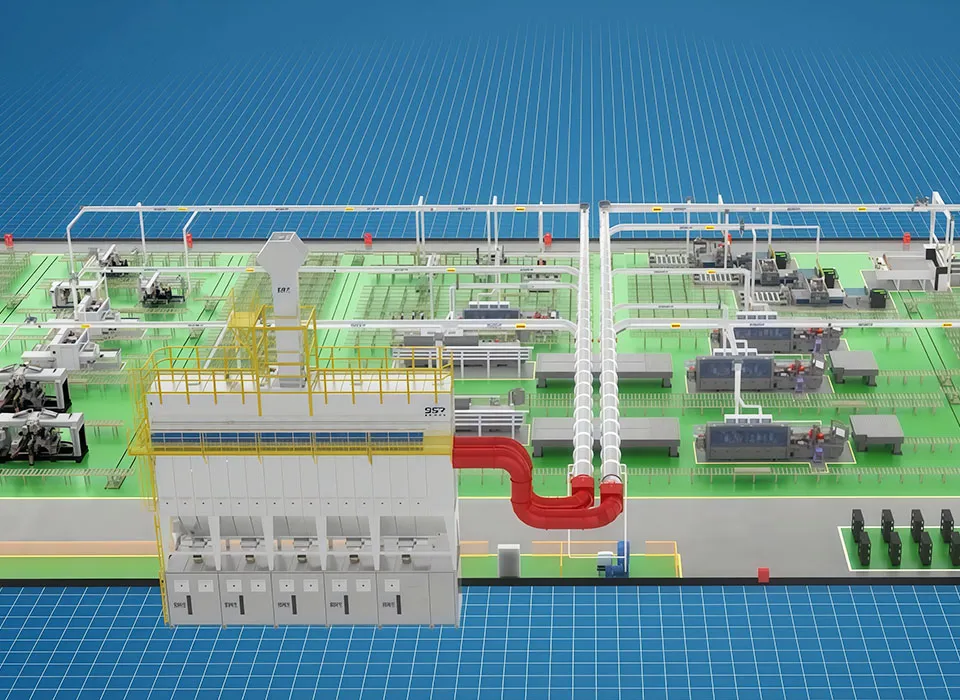

The CC Series is an intelligent modular centralized dust removal system designed specifically for medium and large particle-size dust applications commonly found in heavy manufacturing environments.

Using a multi-fan architecture, built-in fan chambers, and an optimized aerodynamic structure, the CC Series delivers large air volume performance with excellent energy efficiency and operational stability.

The complete product family covers airflow capacities from 30,000–150,000 m³/h, making it suitable for large-scale, multi-line, and continuous-process dust extraction demands.

Its compact built-in fan layout, <80 dB noise control, comprehensive safety sensors, and automated ash-cleaning system make it ideal for factory upgrades, industrial retrofits, and new plant construction requiring strict dust control compliance.

| الطراز | الطاقة (كيلوواط) | حجم الهواء (م³/ساعة) | الطول (مم) | الارتفاع (مم) | High Degree (mm) |

| CC30 | 30 | 30,000 | 3500 | 2400 | 8500 |

| CC60 | 60 | 60,000 | 6000 | 2400 | 8500 |

| CC90 | 90 | 90,000 | 9000 | 2400 | 8500 |

| CC120 | 120 | 120,000 | 11,500 | 2400 | 8500 |

| CC150 | 150 | 150,000 | 13,000 | 2400 | 8500 |

Dust-laden air enters the main chamber, where medium and large particles settle through gravity and directional airflow guidance. Remaining dust is captured uniformly across the filter system.

Real-time monitoring of differential pressure, temperature, and safety triggers maintains optimal filtration performance while ensuring system safety.

Built-in fans operate in a staged manner based on process load, reducing energy waste.

The intelligent ash-cleaning system activates automatically to maintain filtration efficiency without interrupting production.

Step 4: Pulse Cleaning

As dust accumulates, resistance rises. The system triggers pulse-jet cleaning, releasing compressed air to dislodge dust cakes from filters into the hopper below—keeping filtration efficient and uninterrupted.

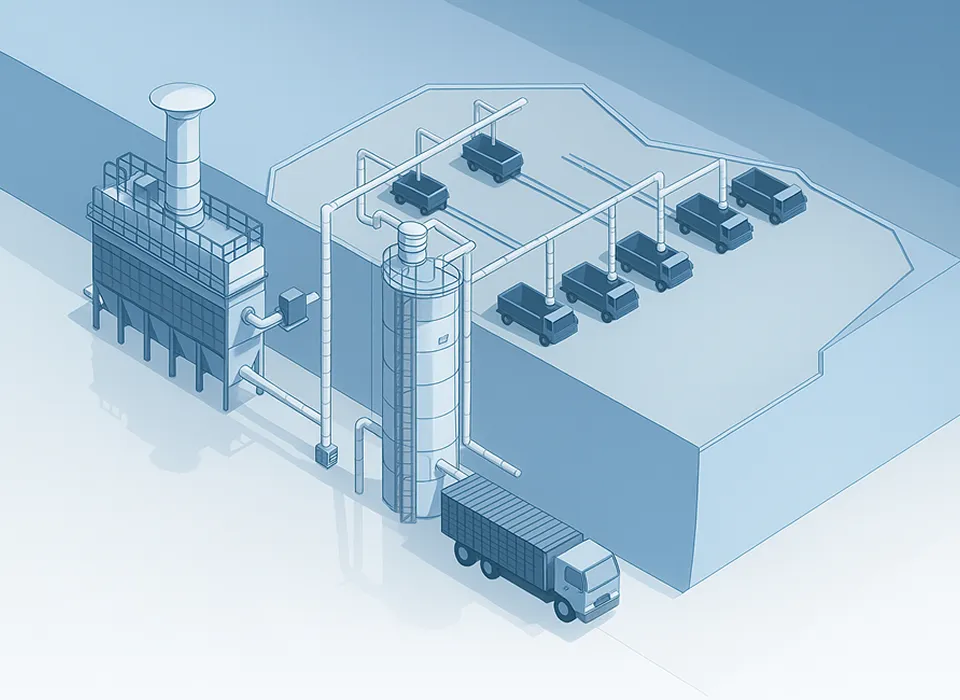

Step 5: Discharge & Collection

Clean air is discharged indoors (to save energy) or outside. Collected dust falls into the hopper and is regularly removed via discharge valves for unified recycling or disposal.

نتعهد بالتسليم في الوقت المحدد ونضع خطط إنتاج وشحن واضحة لكل دفعة من الطلبات لضمان عدم تأخير عقد المشروع الداخلية للعميل.